When it comes to preserving a roof from water-related damage, one component stands out as little yet crucially important: roof drip edge flashing. It may seem like a straightforward metal trim placed at a roof’s edge, but it plays a far bigger role in protecting your house. Understanding how it works, why it matters, and when it should be changed or updated will help you prevent expensive repairs and ensure long-term roof performance.

Although roof drip edge flashing is frequently thought of as a straightforward trim element, most homeowners are unaware of how much of an influence it has on structural protection, moisture control, and roof longevity. Drip edge flashing is a vital defense layer that improves durability, efficiency, and compliance in contemporary roofing systems, going beyond simple water diversion.

What Is Roof Drip Edge Flashing?

Roof drip edge flashing is a thin, L-shaped or T-shaped sheet of metal put around the borders of your roofline. Its major duty is to deflect water away from the roof decking and fascia, preventing water intrusion that can lead to rot, mold, and structural degradation.

Because roof drip edge flashing protects delicate roof margins from moisture, contractors view it as a standard necessity in contemporary roofing techniques. Without it, water can run down the fascia, infiltrate below the gutters, and eventually cause large-scale damage to the home’s exterior.

Read more: What Is TPO Roofing? A Complete Guide for Property Owners

The Role of Drip Edge Flashing in Roof Inspections

Drip edge flashing is a common early warning sign of roof health seen in professional roof inspections. Drainage problems or aged roofing components are frequently indicated by bent metal, loose fasteners, or rust close to the roof edge. Inspectors can identify issues early on—before moisture seeps into the attic, insulation, or wall cavities—by keeping the roof drip edge flashing intact.

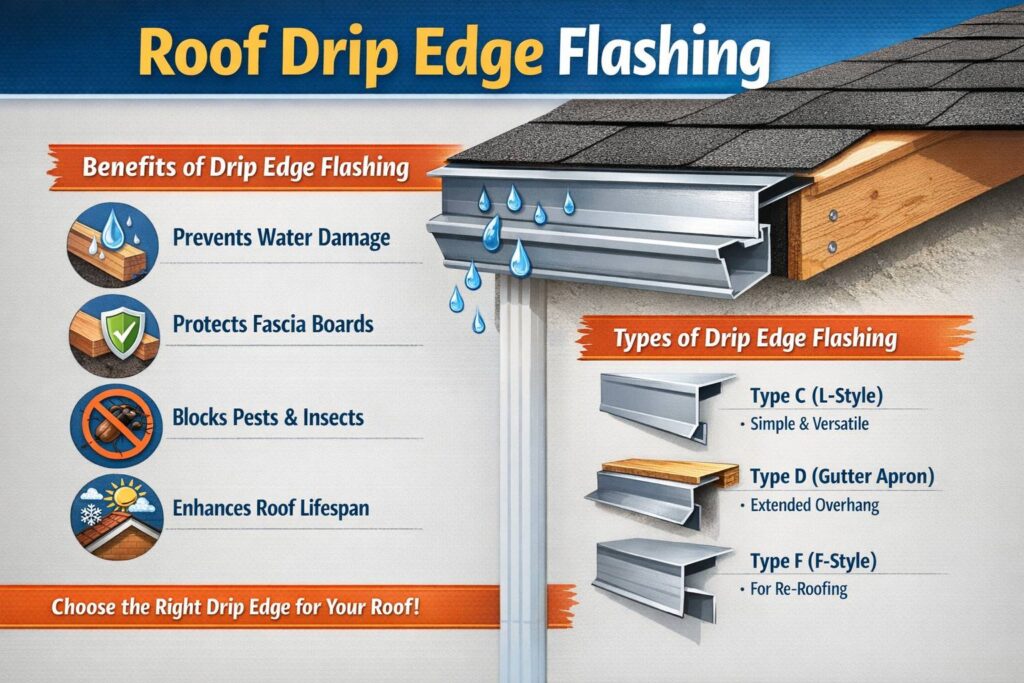

Why Drip Edge Flashing Is Essential for Every Roof

Roof drip edge flashing performs various protective roles, many of which homeowners don’t realize until they suffer from roof troubles. Here’s why it’s essential:

- Prevents Water Damage

The most critical job of drip edge flashing is to force water away from the fascia and roof deck. Rainwater naturally follows gravity, and without flashing, it can creep under shingles and behind gutters.

- Protects Fascia Boards

Fascia wood is very susceptible to rot when exposed to moisture. Flashing eliminates this exposure, prolonging the fascia’s lifespan dramatically.

- Helps Gutters Function Properly

When flashing is built correctly, water is directed straight into the gutters, minimizing overflow and guaranteeing adequate drainage.

- Stops Pest Infestations

Tiny spaces. Insects, birds, and rats may find it easy to enter beneath shingles. Drip edge flashing seals these spaces and limits access.

- Enhances Roof Durability

Flashing prolongs the life of your roof by stopping structural deterioration and water intrusion.

Types of Roof Drip Edge Flashing

There are a number of designs that are appropriate for various roof types and climates. The following are the three most popular forms:

- Type C Drip Edge

The simplest variation, also referred to as the “L-style,” is frequently utilized for roofs with little edge detail. It offers simple water direction.

- Type D (Gutter Apron)

This T-shaped drip edge pulls water farther away from the fascia, making it suitable for homes with heavy rainfall. It also combines seamlessly with gutters.

- Type F (F-Style)

For re-roofing projects where the current fascia needs extra coverage, this extended fascia-style drip edge is great.

When choosing the optimal flashing type, consider roof pitch, climate, architectural design, and gutter positioning.

Read more: Roofing Made Easy: Everything You Need to Know About Roofers in Minneapolis MN

Materials Used in Drip Edge Flashing

Durability and general roof protection are directly impacted by the flashing’s material. The most popular choices are as follows:

- Aluminum

Lightweight and inexpensive, aluminum is the most often utilized option. It is sufficiently flexible to make installation simple and resistant to rust.

- Galvanized Steel

A stronger option that resists corrosion and holds up well under tough weather conditions. Although it is heavier, it is more resilient than aluminum.

- Copper

The ultimate choice for long-lasting, high-end roofing systems. Copper flashing offers unparalleled endurance and gradually takes on a natural patina.

- Vinyl or Plastic

Due to decreased durability and poorer effectiveness in severe weather, it is rarely used nowadays.

Energy Efficiency and Roof Edge Performance

Some of the biggest temperature swings on a house occur along the edges of the roof. Moisture buildup can lessen the efficiency of insulation and increase heat loss if flashing is improper. By keeping roof edges dry, lowering condensation, and assisting in stabilizing interior temperatures—an energy benefit that is sometimes disregarded—roof drip edge flashing promotes improved attic ventilation performance.

How Roof Drip Edge Flashing Is Installed

Correct installation is vital to ensure optimum protection. A badly fitted drip edge may fail to divert water properly, causing the very damage it is supposed to prevent.

Step 1: Installation Under the Underlayment (New Roof)

In new roofing systems, contractors install the drip edge underneath the underlayment on the eaves. This creates a waterproof channel for runoff.

Step 2: Over the Underlayment (Rake Edges)

For rake edges—the sloped sides of your roof—the drip edge is laid over the underlayment. This inhibits wind-driven rain from penetrating.

Step 3: Securing the Flashing

To securely fasten the flashing along the rooftop, roofers use galvanized roofing nails spaced 12 inches apart.

Step 4: Overlapping Sections

Each piece of flashing overlaps the next by at least two inches to enable continuous water flow.

Step 5: Integration With Gutters

The final stage guarantees that water drains directly into the gutter system without splashing behind it.

Your roof system will operate more efficiently and require far less maintenance if it is installed correctly.

Choosing the Right Gauge and Thickness for Your Climate

Thickness is important because not all drip edges are made equal. In warm climates, thin aluminum flashing might suffice, but heavier material is required in areas with high winds, heavy rain, or snowfall. Experts in roofing usually advise:

- Aluminum (.019–.024) for typical home uses

- 26-gauge galvanized steel for regions with a lot of wind or moisture

- Copper in larger gauges for superior, durable protection

The flashing will not bend, warp, or loosen over time if the proper metal thickness is chosen.

Innovations in Drip Edge Design and Technology

Drip edges have become more intelligent and adaptable as roofing technology advances. The sophisticated flashing alternatives available nowadays could be:

Ventilated Drip Edges

These are perfect for controlling attic moisture in humid conditions because they combine water protection with airflow channels.

Pre-Painted and Color-Matched Flashing

In order to help homeowners establish a consistent roofline free of noticeable seams or mismatches, manufacturers now offer drip edges in dozens of hues.

Integrated Drip Edge + Starter Strip Systems

Particularly for re-roofing projects, certain brands provide combination systems that shorten installation times and improve shingle stability.

These developments transform drip edge flashing into a very versatile roofing element rather than merely a straightforward metal trim.

How Moisture Wicking Works at the Roof Edge

One of the main causes of concealed water damage is moisture wicking. Water can gently seep toward the roof deck as it moves down the undersides of the shingles. This is prevented by drip edge flashing, which breaks the surface tension and causes water to fall instead of clinging. By preventing long-term moisture absorption, this tiny disruption helps your shingles dry more quickly and lessens the chance that mold will grow at the roof edge.

Signs Your Drip Edge Flashing Needs Repair or Replacement

Despite flashing’s durability, weather, rust, and incorrect installation can cause it to deteriorate over time. Here’s what to watch for:

- Water Streaks on Fascia Boards

If fascia paint is flaking or you observe moisture marks, it may indicate water intrusion behind the gutters.

- Gutter Overflow During Rainstorms

Runoff can be misdirected by defective flashing in addition to clogged gutters.

- Rotting Fascia or Soffit

Flashing failure is indicated by wood rot brought on by prolonged exposure to moisture.

- Visible Gaps

Any gap between shingles and flashing is a huge concern.

- Rust or Corrosion

Metal flashing exposed to continuous moisture will deteriorate over time.

- Pest Activity

Small animals or birds building their nests close to the roofline may indicate gaps in the flashing.

Read more: A Step-by-Step Guide to Estimating Roofing Squares for Homeowners and Professionals

Maintenance Tips to Extend the Life of Your Drip Edge

Although drip edge flashing often requires little upkeep, regular maintenance guarantees peak performance:

- Gutter cleaning should be done twice a year.

- Inspect shingle edges for lifting.

- Check for loose nails or moving of flashing portions.

- Look for corrosion or cracks on metal surfaces.

- Make sure gutters are firmly fastened to the fascia.

A 15-minute seasonal inspection can prevent hundreds of dollars in repairs.

Why Building Codes Require Drip Edge Flashing

Drip edge flashing is required for all residential roofs under the majority of contemporary construction regulations, notably the International Residential Code (IRC). The reason for this need is:

- It stops the deterioration of roof decks.

- It enhances water management.

- It prolongs the life of roofs.

- Long-term maintenance is decreased.

Your contractor is required by law to incorporate drip edges into the project if you are replacing a roof.

Roof Drip Edge Flashing in Extreme Weather Climates

Roof drip edge flashing is especially beneficial for homes in areas with high rainfall, snow buildup, or strong winds. In snowy climates, ice dams can cause considerable roof damage, but drip edge flashing helps channel meltwater into the gutters instead of back under the shingles.

Wind-prone places also require deeply rooted flashing to prohibit shingles from lifting and exposing bare roof decking.

Cost of Installing or Replacing Drip Edge Flashing

Costs depend on materials, roof size, and labor costs. This is a broad summary:

- Aluminum: $1 to $2 for each linear foot

- Steel: $2–$4 per linear foot

- Copper: $10 to $20 for each linear foot

Professional installation for an average home normally costs $150–$500, commonly included in roof replacement projects.

DIY vs. Professional Installation

Although do-it-yourself installation is feasible, experts typically yield more durable, code-compliant outcomes. Think about using a roofing specialist if:

- Your roof has a steep pitch

- You’re working close to power wires.

- Your gutters are complex

- You don’t know how to incorporate the underlayment.

Professionals also verify that flashing is adequately sealed and wind-resistant.

Read more: Why Professional Storm Damage Roof Repair MN Is Essential After Every Minnesota Storm

Roof Drip Edge Flashing Installation: Professional-Level Insights

Fewer instructions address installation subtleties that affect long-term roof performance, even though the majority define drip edges. The type of roof, local construction requirements, and environment all play a major role in the proper installation of roof drip edge flashing.

The drip edge should be placed above the underlayment on rakes and beneath the underlayment at the eaves of asphalt shingle roofs. Because of its arrangement, water cannot back up under shingles during periods of severe rain or ice jams. Drip edges of metal roofing systems frequently integrate directly with panels, necessitating exact attaching spacing to avoid warping caused by expansion.

The choice of fastener is also important. The recommended spacing for corrosion-resistant roofing screws or nails is eight to twelve inches. While under-driving fasteners may let wind uplift, overdriving fasteners might distort the flashing. In order to prevent capillary water intrusion—a frequently disregarded procedure that increases durability—professional installers routinely seal connections at corners.

Roof Drip Edge Flashing Colors: Functional and Aesthetic Considerations

Roof drip edge flashing colors are becoming a crucial design feature rather than an afterthought since homeowners are becoming more conscious of how roof components appear.

White, black, brown, gray, bronze, and custom-matched finishes are just a few of the many colors that drip edge flashing comes in. A unified appearance with shingles, fascia, gutters, and siding can be achieved by selecting the appropriate color. For instance, brighter hues go well with modern or coastal designs, while darker hues go well with architectural shingles.

Color affects fading resistance and heat absorption in addition to attractiveness. In hot areas, lighter hues may marginally lessen thermal stress on roof edges since they reflect heat. Generally speaking, factory-coated aluminum drip edges with baked-on finishes are more resistant to peeling, chipping, and UV damage than painted alternatives.

Roof Drip Edge Flashing Menards: What Homeowners Should Know

Roof drip edge flashing Menards is a popular search keyword since many homeowners shop at big-box stores. Menards offers a variety of shapes, lengths, and colors of galvanized steel and aluminum drip edge flashing that can be used by contractors and do-it-yourselfers.

In order to reduce seams and expedite installation, standard lengths are usually 10 feet. Additionally, Menards carries pre-finished colors that complement popular gutter systems, making coordination for outside renovations easier.

Before making a purchase, consumers should carefully consider the type of profile and thickness of the material. Some professional-grade drip edges have thicker gauges and reinforced hems that work better in high-wind or snow-prone areas, even though retail options are more affordable.

Why Professional Installation Matters

Even while drip edge flashing seems simple, minor installation mistakes can reduce its efficacy. Water may be redirected toward the structure rather than away from it due to improper overlap, improper fastener placement, or poor positioning in relation to the underlayment. For optimal protection, skilled roofers make sure roof drip edge flashing complies with local regulations, roof design, and climate conditions.

Roof Drip Edge Flashing Detail: Design Features That Matter

Homeowners can better understand why different drip edges function differently by knowing the specifics of roof drip edge flashing. Subtle design features that improve operation are present in high-quality drip edge flashing.

By preventing sharp edges and increasing rigidity, a hemmed edge lowers the possibility of damage during installation. Water is diverted off the fascia by a correctly angled kick-out at the bottom edge, preventing rot and paint damage.

In order to improve water capture during periods of high rainfall, some drip edges include an expanded flange that is made to operate with contemporary gutter systems. Others are designed to fit ice-and-water shield membranes, which are essential in cold areas.

These seemingly insignificant elements have a big impact on the roof edge’s ability to withstand moisture penetration over time.

When Upgrading Drip Edge Flashing Makes Sense

It is especially advantageous to add or upgrade drip edge flashing during:

- Roof restorations or replacements

- Fascia repairs or gutter replacement

- Restoration of storm damage

- Updates on code compliance

Upgrades are a wise investment for both performance and resale value because drip edge flashing is now required by many modern construction codes.

Long-Term Value of Roof Drip Edge Flashing

Roof drip edge flashing offers a remarkable return on investment, from preventing structural deterioration to enhancing roof performance during storms. It is among the most economical roofing modifications available due to its comparatively cheap cost when compared to fascia replacement, deck repairs, or mold remediation.

Common Myths About Drip Edge Flashing

Myth 1: It’s Not Necessary on All Roofs

It is mandated by nearly all contemporary roofing codes, and for good cause.

Myth 2: Gutters Are Sufficient on Their Own

Gutters catch water; flashing directs it. Both are necessary.

Myth 3: You Can Use Any Metal

Use only authorized metals that are resistant to corrosion.

Conclusion – Protect Your Roof with Smart Choices

Roof drip edge flashing may be a little component, but it performs a crucial role in protecting your property against water damage, pests, gutter malfunctions, and premature roof deterioration. Your roofing system will last longer and avoid expensive structural problems if it is installed, maintained, and changed as needed. One of the best choices you can make for your house is to get premium roof drip edge flashing.

Despite its small size, roof drip edge flashing makes a significant contribution to roof protection. It strengthens overall roofing performance, increases drainage efficiency, and protects roof edges whether it is added during an upgrade or installed on a new roof. Purchasing premium roof drip edge flashing is a wise choice that safeguards your house and your long-term maintenance budget.